QUALITY ELECTRICAL CABLE PRODUCTION PROCESS – PART 1: WIRE DRAWING

Have you ever wondered why electrical cables can sometimes be very stiff for underground use or overhead installation, but also very flexible and easy to bend and connect in various home spaces?

Join DAPHACO to explore the manufacturing process of electrical cables, starting with the first step: the wire drawing stage..

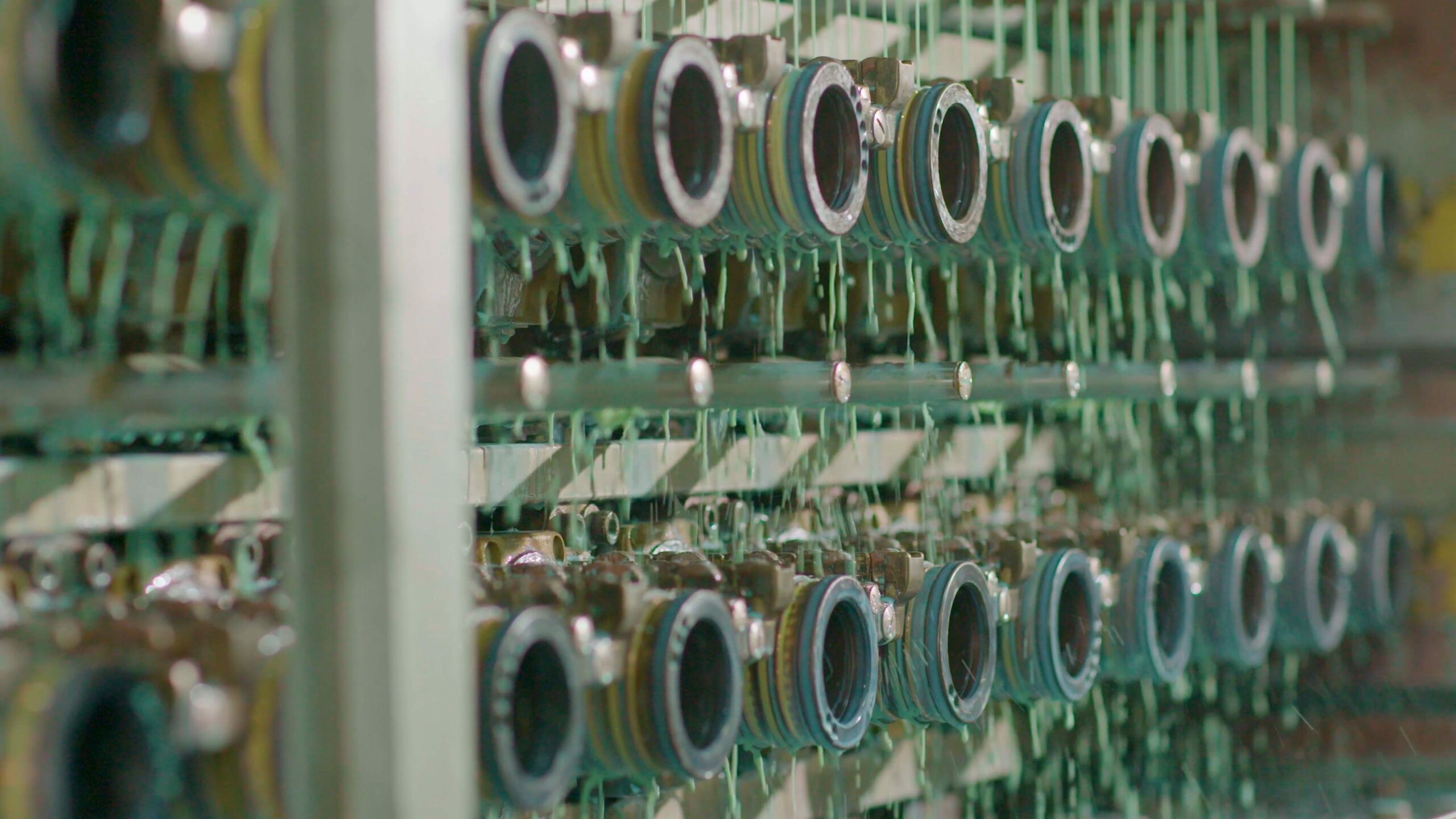

Originating from raw copper coils, they are discharged through wire guides and continue to be fed to the tractor. Then the copper wire is passed through the system of drawing dies thanks to the pulling force created by the drawing drum of the drawing machine when wrapping the output end of the wire on the drawing drum. Here, the circulating pump system will pump oil to cool the drawing mold head, reduce the temperature due to friction and at the same time act as a lubricant and protect the mold. DAPHACO uses large drawing machines (From 8.0mm to 1.04mm) and multi-way fine drawing machines (From 1.8mm to 0.12mm), the copper wires will be reduced in diameter by lengthening the wire length to until the appropriate wire size is achieved through shaping molds with standard sizes.

The raw copper wires are discharged through wire guides

The raw copper wires are discharged through wire guides

The raw copper wires are discharged through wire guides.

The raw copper wires are discharged through wire guides.

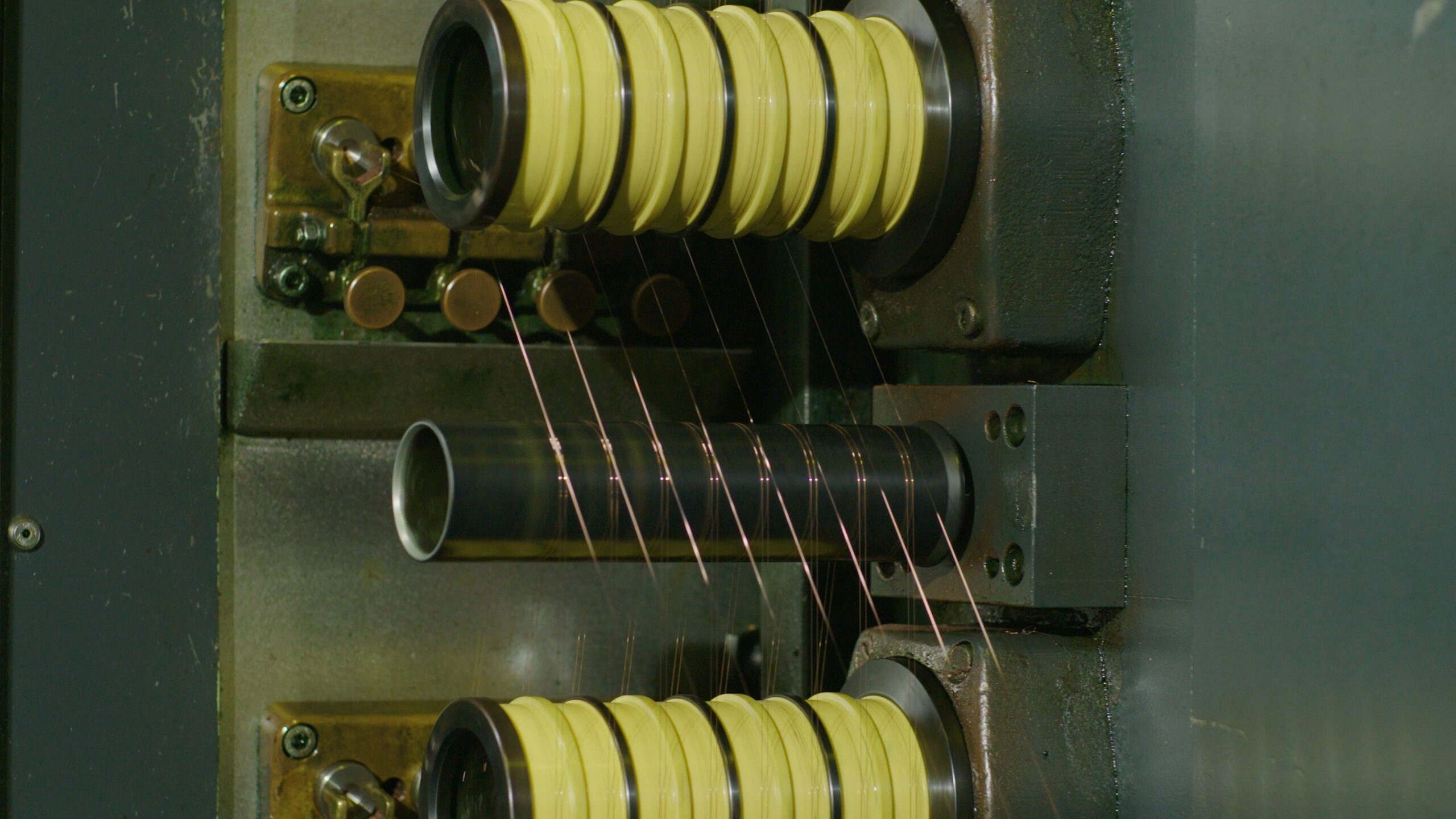

Next is the annealing process to soften the wire with the purpose of reducing tensile strength, increasing elongation, eliminating residual stresses, balancing the metal crystal lattice, eliminating the hardening state of the metal after the drawing process, and helping to restore the metal’s hardness. restore mechanical properties according to technical requirements. Soft annealing is the process of heating metal in an inert, non-oxidizing environment (such as vacuum, saturated steam, nitrogen gas, etc.) up to a specified temperature depending on the type and size of the temperature-retaining fiber. for a specified time and continue to cool to ambient temperature.

Copper wires are guided into the annealing chamber system, making the wire flexible and shiny.

Copper wires are guided into the annealing chamber system, making the wire flexible and shiny.

DAPHACO applies modern technology with continuous annealing equipment that allows pulling out copper wires of all sizes while still ensuring connection and not breaking, helping to restore the flexibility and shine of the copper wire.

DAPHACO applies modern technology with advanced equipment at the spinning stage.

DAPHACO applies modern technology with advanced equipment at the spinning stage.

Finally, the copper or aluminum wire is collected into the bobbin to prepare for the next step, which is the winding of the conductor.