Control Cables

CY – 300/500V

YY – 300/500V

Control cables are one of the specialized cables widely used in industrial equipment and machinery systems. Currently, there are many types of control cables on the market, including LION control cables. Refer to the article below and we will provide detailed information about this product!

Overview of Control Cables

Control cables are specialized electrical cables used to transmit control signals from central devices (such as PLC controllers, relays, or sensors) to end devices (such as solenoid valves, industrial machinery and motors). These cables are primarily used in automation systems, industrial control systems, or systems requiring precise signal transmission.

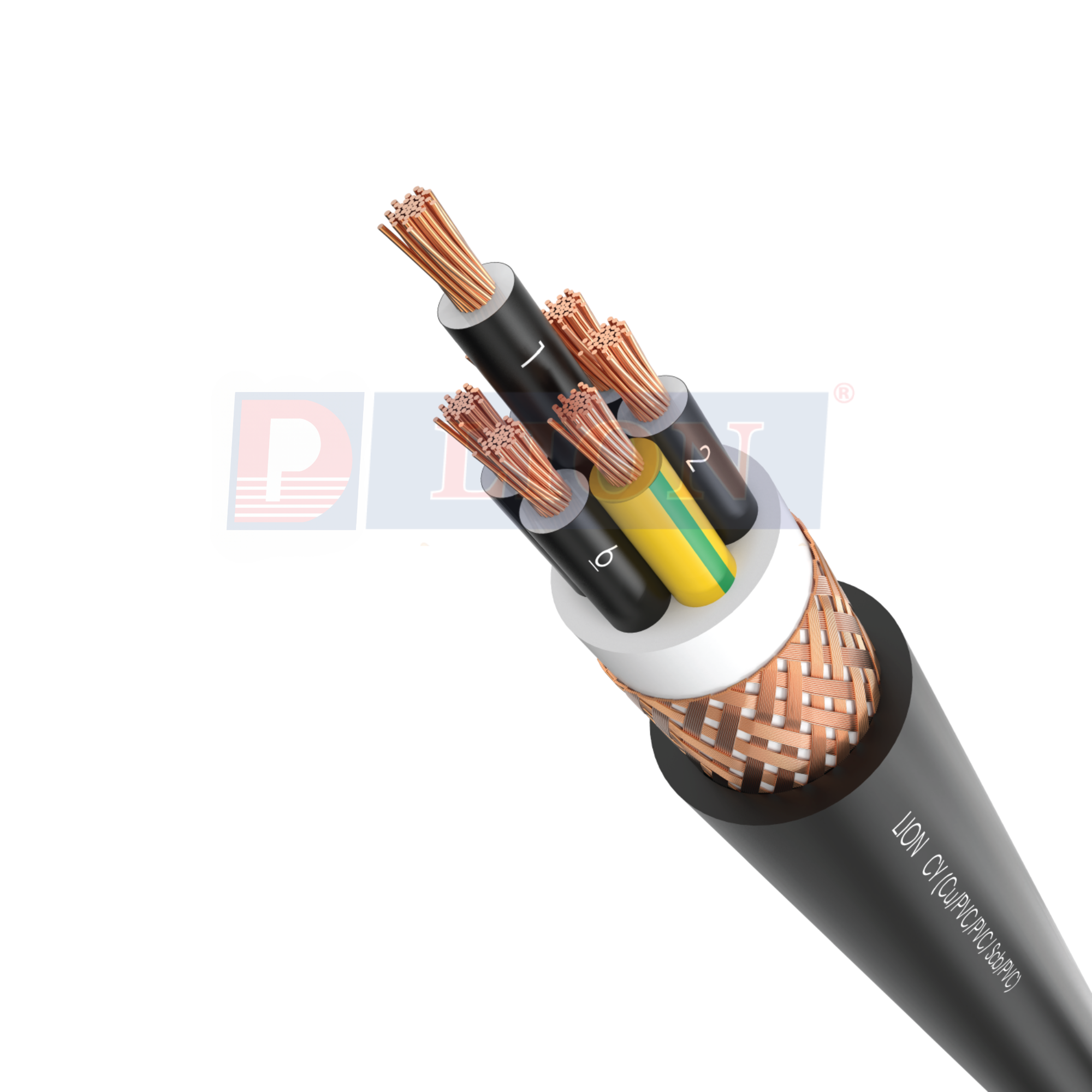

Structure of Control Cables

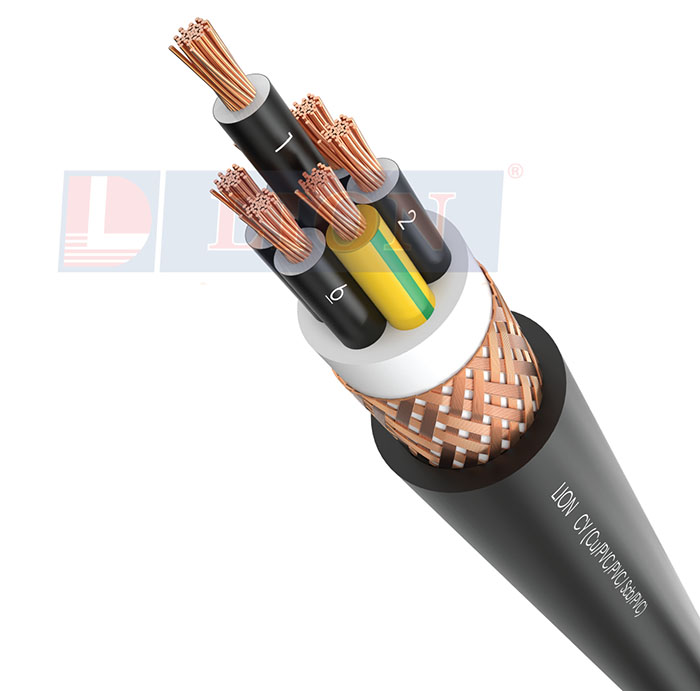

Control cables typically consist of the following four main components:

Conductor Core: Made of pure copper, the core is twisted into a round or segmented shape depending on the type.

Insulation Layer: Made of cross-linked polyethylene (XLPE) or high-quality PVC.

Core Assembly: Used to bundle multiple copper cores together. The number of cores varies depending on the cable design. The core sheath is usually black or colored as required.

Separator Layer: Made of polyethylene (PE) or high-quality PVC, which is flame-retardant and can withstand temperatures up to 800°C.

Applications of Control Cables

Control cables are used to transmit low-voltage signals such as voltage signals, resistance signals, analog signals and digital signals. They are used in the following scenarios:

Control cables are used in manufacturing plants to operate modern automated machinery.

They are also used in crane systems.

Additionally, they are used in air conditioning or heating systems in buildings.

Common Types of Control Cables

LION control cables are one of the trusted brands chosen by customers. To meet customer needs, the manufacturer has divided the product into two types: shielded control cables and unshielded control cables. Below is detailed information about these two types for your reference:

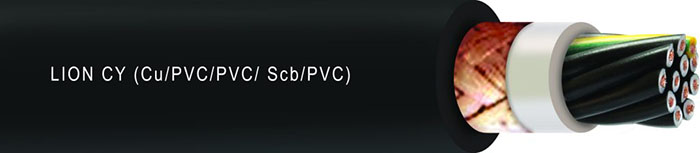

CY – 300/500V LION Control Cable

The CY – 300/500V LION control cable is a shielded cable with PVC insulation and oil-resistant PVC sheathing. The conductor can withstand a maximum temperature of 70°C during use. The product is used for control circuits with a frequency of 50Hz and is designed for fixed installation.

YY – 300/500V LION Control Cable

The YY – 300/500V LION control cable is an unshielded cable with PVC insulation and oil-resistant sheathing. It is used for control circuits with a frequency of 50Hz and is designed for fixed installation at a voltage of 300/500V.

Key Features of Control Cables

Control cables are preferred due to their outstanding technical characteristics:

Excellent Signal Transmission

Control cables ensure accurate and stable signal transmission. They also have anti-interference properties, preventing signal loss or weakening during use.

Anti-Interference and Stable Signals

The structure of control cables includes a layer of braided or copper tape shielding, which effectively prevents signal interference, ensuring safe and stable signal transmission.

Heat and Fire Resistance

These cables can withstand high temperatures, up to 160°C during short circuits and a continuous operating temperature of 70°C under normal conditions.

Insulation and Safety Protection

Control cables comply with Vietnamese and international technical standards such as TCVN 5935 – 1995, TCVN 661, TCVN 60502 and IEC 62067.

How to Choose the Right Control Cable

To select the appropriate control cable, consider the following criteria:

Voltage Rating

Voltage is one of the most important criteria when choosing a control cable. You can determine the voltage rating through the cable markings, such as 300/500V. This information can also be found in technical documents or system design requirements.

Number of Cores and Conductor Size

Determine whether the conductor size and number of cores are suitable for your system. Experts recommend selecting the conductor size based on power and signal transmission distance:

Control cables with a cross-section of 0.5mm² – 1.5mm² are used for standard control signals.

Cables with a cross-section of 2.5mm² – 6mm² are used for systems requiring absolute precision and long-distance signal transmission.

Operating Environment

Consider the operating environment when selecting a control cable. For environments with electrical interference, such as factories or workshops, choose shielded control cables. For normal environments with minimal interference, unshielded cables can be used to save costs.

Reliable Control Cable Supplier in Vietnam

After determining the selection criteria, the next important step is choosing a reliable supplier. You should opt for control cables from reputable companies with years of experience in the market. Daphaco Cable Joint Stock Company, with its extensive experience in manufacturing and distributing electrical cables in Vietnam, is a top choice for your reference.

Currently, the company distributes LION control cables, a high-quality product manufactured using advanced technology. These durable cables are trusted by many companies, enterprises and large corporations.

For customers interested in purchasing genuine LION control cables, visit the website: https://daphaco.com/en/ for the best advice and support!